VIG PRODUCTION

INTRODUCTION to VIG

The concept of VIG is not new. It was first described in the patent literature by Zoller in 1913. however, it was 1989 before the successful fabrication of a VIG was reported by Collins at the University of Sydney. In simple terms, a VIG is a double-glazing unit where the air between the two panes of glass has been extracted, creating a partial vacuum. enuation of noise is improved over almost all frequency ranges relative to an IGU, but particularly in the mid-frequency range where noise from traffic and public transport is prevalent.

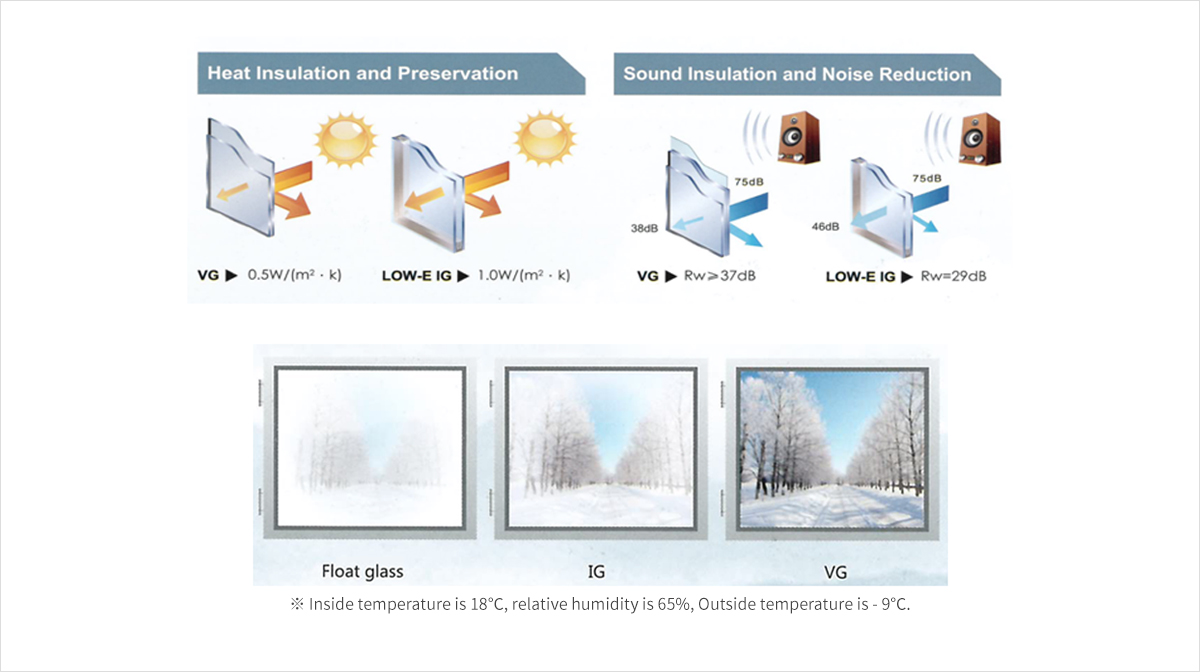

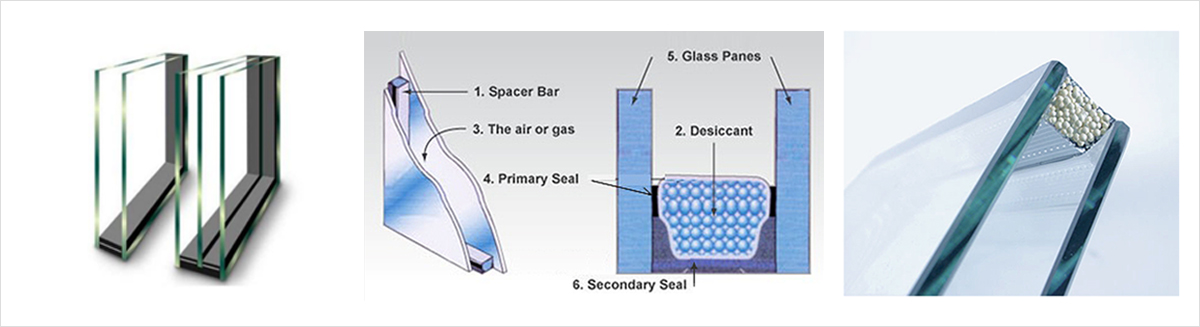

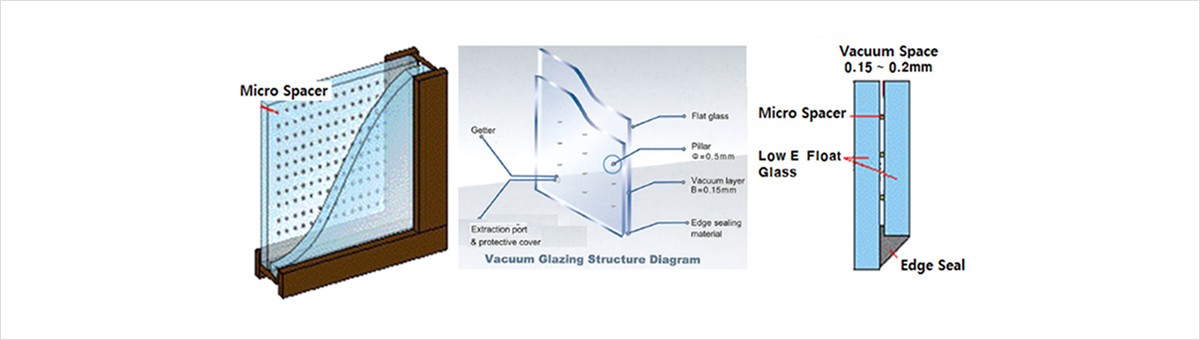

A vacuum provides excellent thermal efficiency because if the pressure is low enough, it will eliminate the conductive and convective heat exchange between the two panes of glass. In a standard double-glazed unit with a Low-E coating, the conduction/convection component can result in 70% of the heat lost; so eliminating this loss is significant. As will be described in more detail below, the radiative heat loss can then be reduced using a Low-E coating inside the VIG, producing an even lower U-factor. Due to the efficiency of a vacuum in reducing heat loss, it is not necessary to have a large distance between the two panes of glass the typical distance is 0.2 mm.

This signifies a conventional IGU, which will generally have an air space of around 12 mm. As a result, VIG units can have an overall thickness of as little as 6.2 mm, comparable to a monolithic piece of glass but with the performance of a triple glazed insulated glass unit. The current state-of-the-art in terms of U-factor for a commercially available 6.2 mm thick VIG is lower than 0.6 W/m2K.

The thin form factor of VIG is a key feature, as this gives many new opportunities to building designers and architects in projects where it is not possible to increase the thickness of the glazing beyond ~6 mm. In these situations, heat loss through monolithic glazing is significant and VIG can provide significant benefits to energy efficiency without compromising the aesthetics or design of the building.

The reduced thermal conductivity of VIG also provides increased condensation resistance.

Condensation can be a major issue in buildings, both from an aesthetic standpoint and due to the damage, it can cause to window frames and other building materials.

For a 6.2 mm VIG with a U-factor of 1.4 W/m2K(with the window frame), installed in a room with internal conditions of 20 °C and 60% relative humidity, no internal condensation will form at external temperatures down to –21 °C. Identical tests using a conventional 12 mm IGU with Low-E resulted in condensation forming at temperatures around 0 °C.

A further advantage in the use of a VIG can be seen in its sound reduction performance relative to a conventional IGU. Due to the use of a vacuum betwee the panes, the attenuation of noise is improved over almost all frequency ranges relative to an IGU, but particularly in the mid-frequency range where noise from traffic and public transport is prevalent.

THE PAIR GLASS STRUCTURE

THE VIG STRUCTURE

THE VIG EFFECT